Introduction

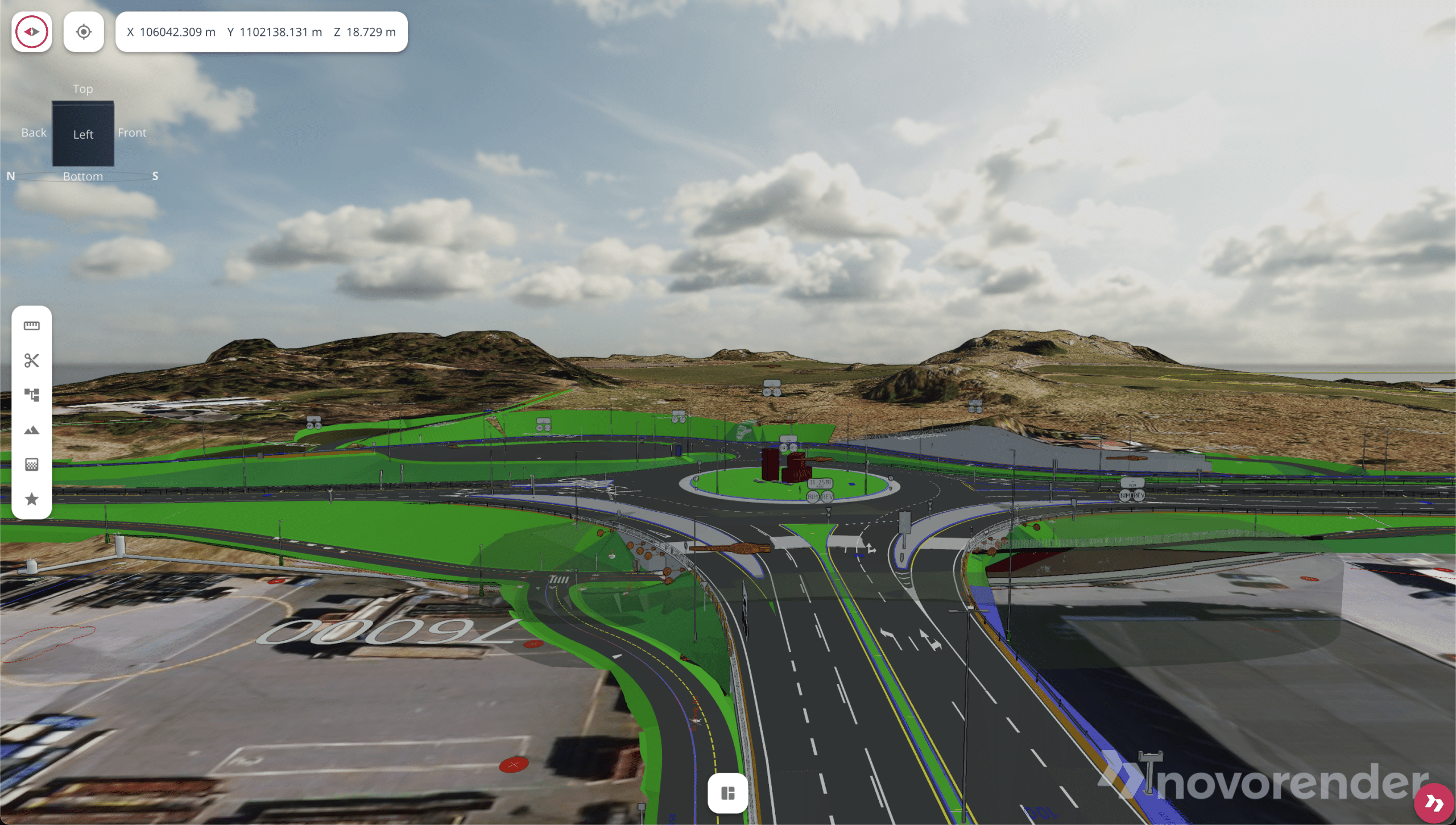

Transport Corridor West is a 13-kilometre-long road and critical infrastructure in the south-western part of Norway. When the Norwegian Public Roads Administration (Nw.: Statens vegvesen) announced the project to upgrade a major section of the road (Sør-Tjora–Kontinentalvegen, known as RV509) it also decided that the project would be an arena for innovation in digital construction. This opened the door for BIM and model-based construction. With the goal of pioneering innovation in the construction industry, improving quality and enhancing collaboration between the contractor, design engineer, and the owner, the project was carried out using a fully model-based and paperless approach. This introduced a new use of BIM models in the construction sector for the parties involved. As the main contractor, Bjelland chose the digital platform Novorender to ensure real-time updates and easy access to information for all stakeholders.

From Traditional Drawings to 100% Model-Based

Traditionally, infrastructure design and construction have relied heavily on extensive 2D drawings and associated fragmented information flow. In the RV509 project, this approach was challenged by eliminating printed drawings and replacing them with a continuously updated 3D model accessible online to all project team members. This model would not only federate all BIM on the project, but it would also be the foundation for the actual construction. This allowed design engineers, project managers, construction workers, as well as machine operators to always work with up-to-date information without delays driven by revisions and physical paper distribution.

Choosing Novorender

When evaluating 3D viewers for model-based project visualization and management, Bjelland chose Novorender after rigorous testing. Bjelland’s formerly used tools struggled with loading times and ability to visualizing large, complex 3D models—especially in projects involving multiple disciplines—which led to lagging and unstable user experiences, which in turn hinder adoption and use, especially in the field.

Novorender, on the other hand, excelled in its ability to handle multiple heavy and complex 3D models simultaneously without performance loss. The platform provides seamless and efficient viewing directly in a web browser, enhancing collaboration and insight across the organization.

This choice ensures that Bjelland can execute model-based projects effectively supported by a scalable and future-proof platform that can accommodate the ever-growing BIM requirements on large, infrastructure projects.

Challenges

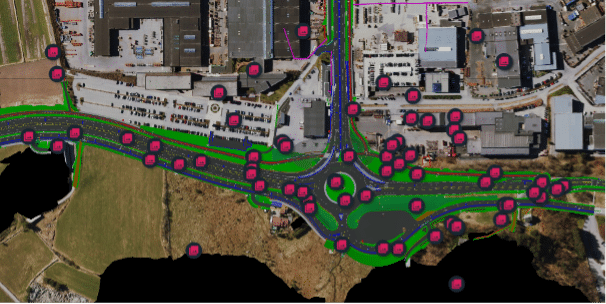

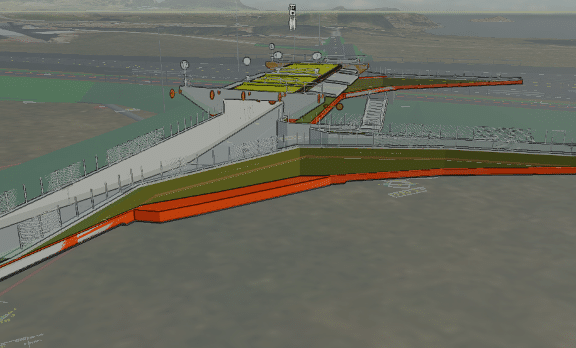

The project aimed to increase traffic capacity, reduce congestion, and improve access to industrial areas and ports by upgrading a two-lane road to a four-lane road. This also included expansion of public transport options, extensive cycling and pedestrian paths, and nearby municipal roads.

Tight construction timelines, combined with the need for interdisciplinary collaboration and rapid planning and approval, created significant logistical and administrative challenges for the project. Traditional execution of such projects typically takes 4 years, but the team aimed to reduce this timeline significantly. Thanks to good cooperation and tools like Novorender, it became possible to collaborate from early phases more efficiently.

Benefits:

Real-time updates and effective collaboration

One of the biggest advantages of this approach was the ability to make real- time updates to designs and construction plans. With Novorender, engineers and construction workers could instantly view changes in the model, reducing errors and uncertainty on the job site. Instead of waiting for updated drawings, workers could use tablets and mobile phones to directly access the latest information — including material quantities, positioning of structures, and quality assurance checklists.

Reduced construction time and improved resource efficiency

By integrating Novorender into the construction process, the project was able to achieve a significant reduction in construction time. Unlike traditional methods—where detailed design is typically completed before construction begins — the model-based approach enabled construction to start in parallel with detailed design, without compromising quality, health and safety (HSE), or execution efficiency. As a result, the total project duration was reduced from an estimated 4 years to just 2.5 years.

Additionally, digital material management helped minimise waste in ordering concrete, steel, and other resources. Using Novorender, the contractor could accurately calculate the required material quantities directly from the 3D model, leading to both cost savings and a more sustainable project execution.

Quality control and documentation

Another key aspect of the project was the improvement in quality assurance and documentation. Previously, this was managed using paper-based checklists and photographs stored in fragmented systems. With Novorender, workers could take photos directly in the field and place them in the 3D model with georeferencing. This made it easy to link documentation to specific locations within the project, streamlining inspections and final quality control.

Improvements for next project

The experience from the RV509 project has provided us with valuable insights into how model-based and paperless execution can streamline both planning and construction. At the same time, we’ve identified several areas for improvement that we will carry forward into our next project — to ensure even broader adoption and even greater value in the field.

One of the focus areas going forward will be bringing the digital model even closer to the actual construction work. This includes equipping each machine with a tablet – instead of the previous setup, which relied on a smaller number of tablets and mobile phones shared. In addition, navigating the model is more intuitive and effective on tablets than on mobile phones. By providing machine operators with direct and easy access to the model, we reduce reliance on intermediaries or office-based support.

We also recognise the need to make the model even more user-friendly, with simplified representations and a lower barrier to finding the information a user needs – especially for field workers with limited experience using digital tools.

Moving forward, we aim to improve the model structure to make information more accessible and searchable, while also improving support for parametric quantity takeoff through more suitable file formats and clearer categorisation. This will contribute to greater accuracy and improved resource management throughout the entire project.

Another important measure will be to establish cross-disciplinary alignment early in the project. This involves the owner, design engineer, contractor, and subcontractor jointly agreeing on how the model will be used, what it should contain, and which needs it must meet. This will foster a shared understanding and enable more targeted and effective use of the model throughout the entire project lifecycle.

Finally, Bjelland will work more actively with both the owner and subcontractors to gain broader acceptance and wider practical use of the digital model. Increased ownership and involvement from all parties are crucial to realizing the full potential of a model-based approach.

Conclusion

The transition to a fully digital, model-based construction process on the RV509 Transport Corridor West project has proven to be a great success, resulting in a greatly reduced timeline from 4 to 2.5 years and reduced environmental impact. By replacing paper drawings with a digital platform and utilizing real-time updates and mobile accessibility, the project has set a new standard for future infrastructure projects. The insights gained in the project will provide valuable lessons learned for upcoming projects aiming to move toward a more digitalized and sustainable construction industry.

The benefits of the model-based approach will be substantial. We expect fewer misunderstandings and errors in construction, faster decision-making processes, and better utilization of both time and resources. A more accessible and structured model foundation will increase confidence in construction, improve documentation along the way, and reduce deviations. Perhaps most importantly, it will create a shared digital language among all project participants — crucial for both effective collaboration and high-quality deliverables. Based on the experience from RV509 Transport Corridor West, Bjelland is convinced that model-based execution is here to stay. This is the future.

For questions or more information, please contact:

Head of Surveying, Bjelland

alexander@bjelland-as.no

+47 992 80 585

Chief Operating Officer, Novorender

pal@novorender.com

+47 915 83 207